Accurate PCB inspection

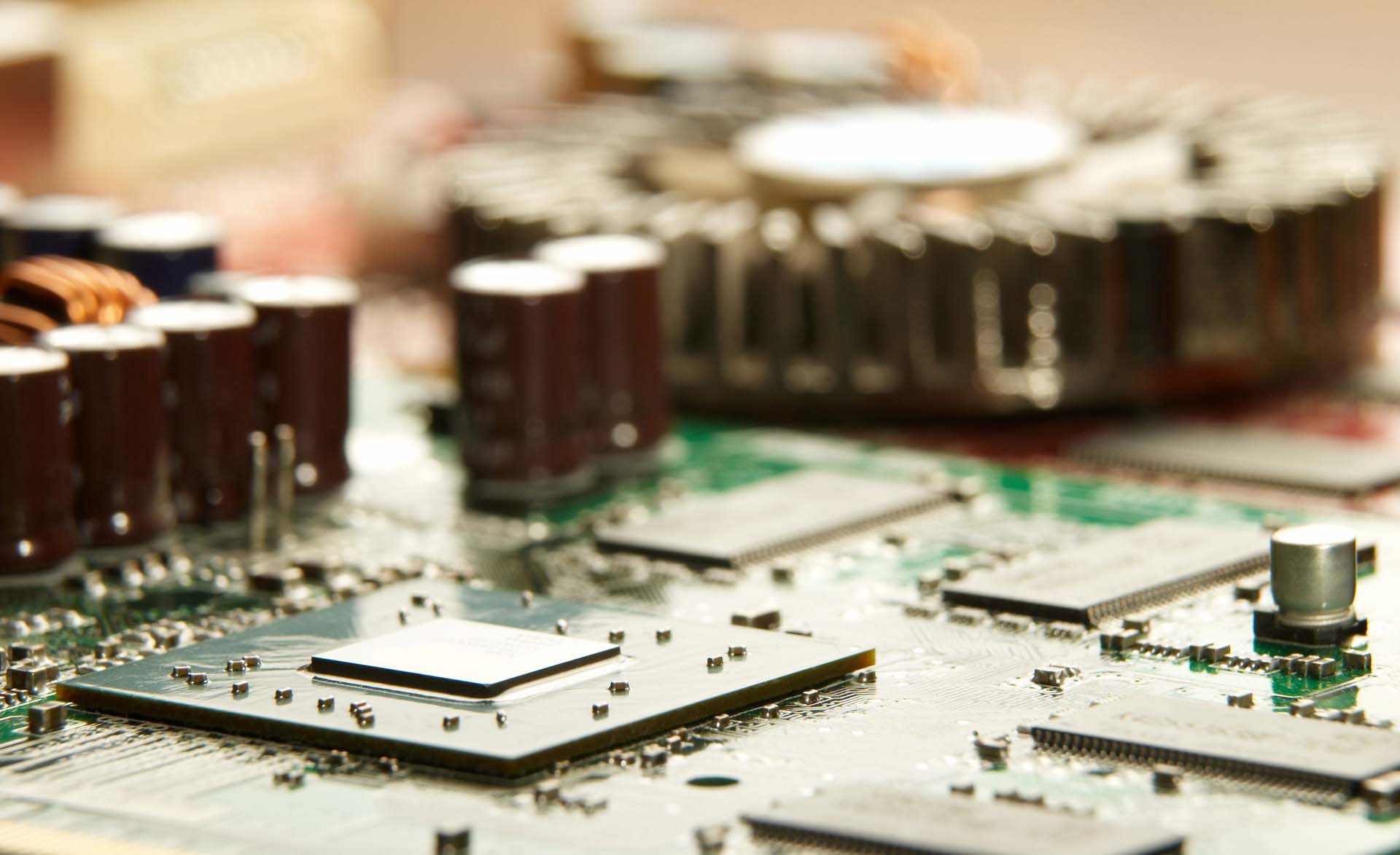

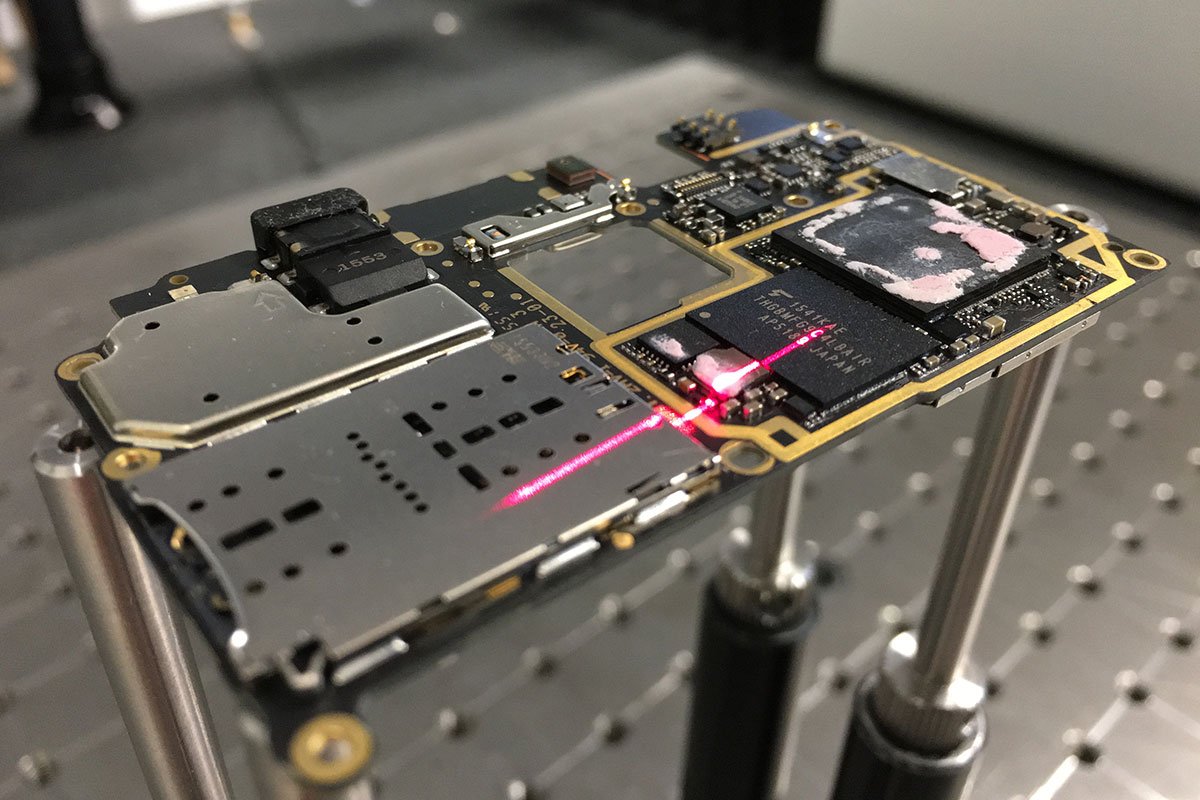

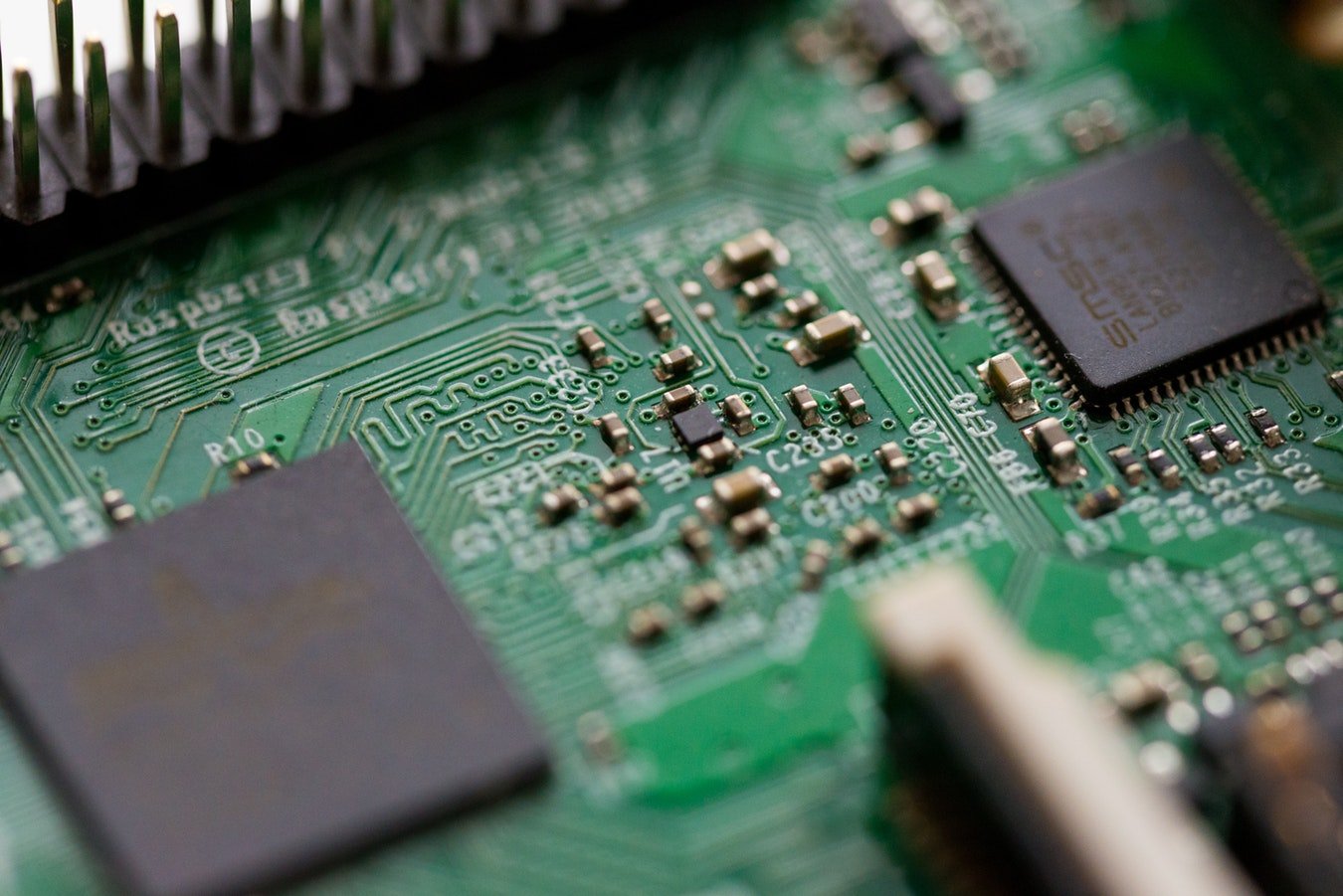

Manufacturers of advanced PCB (printed circuit boards) know that simultaneously producing cost competitive products and meeting the quality expectations of customers are vital to their success. Identifying the PCB shorts, PCB voids, opens, misalignments and solder integrity of area-array chip packages is crucial. We manufacture several variations of machines that measure coplanarity of PCB components.

Component placement

Companies use 3D Profiler to create custom products to inspect the proper number, size, and placement of components on printed circuit boards. 3D Profiler enures that each PCB has all the components it needs properly positioned before being installed into other devices. Our 3D Scanning Systems reduce company costs by identifying improperly seated components before they are soldered onto the PCB. This allows the manufacturer to increase quality and decrease costs at the same time.